IQ5 Glassware Washer

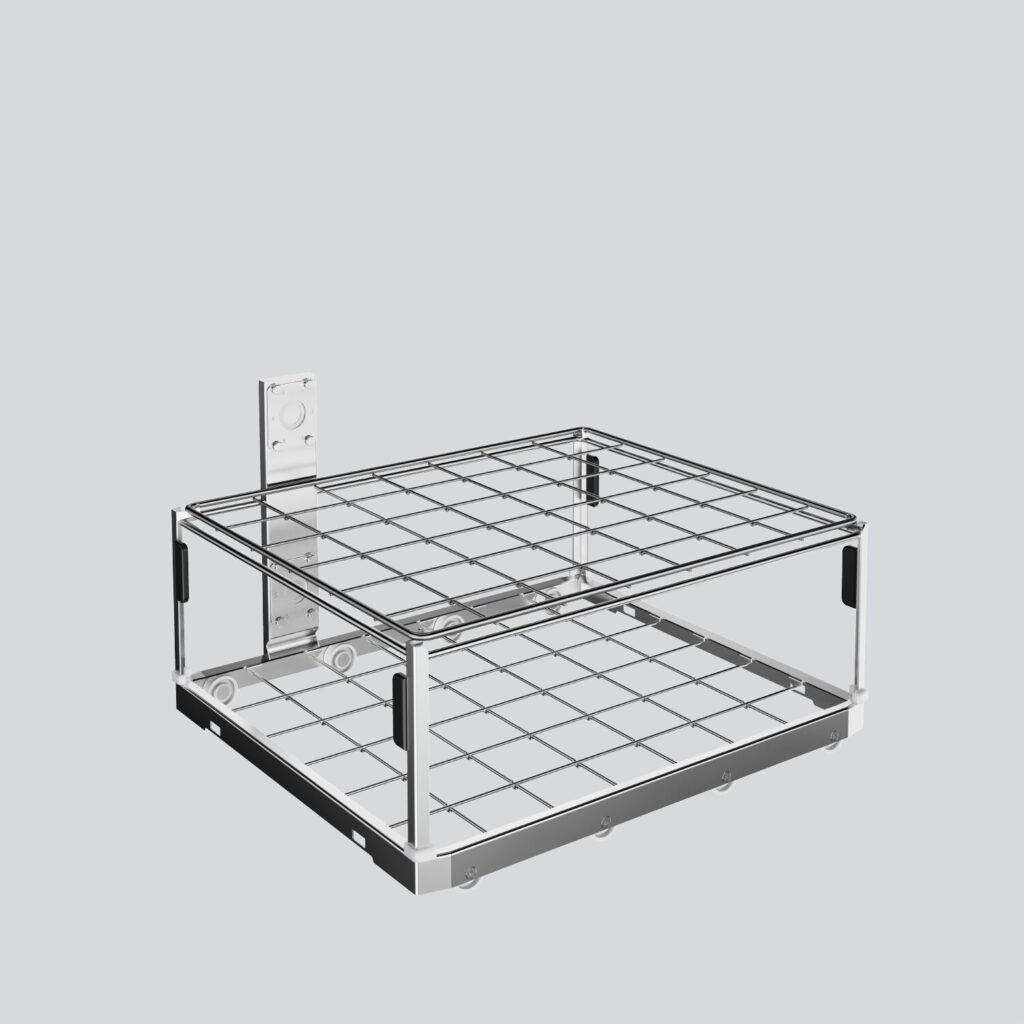

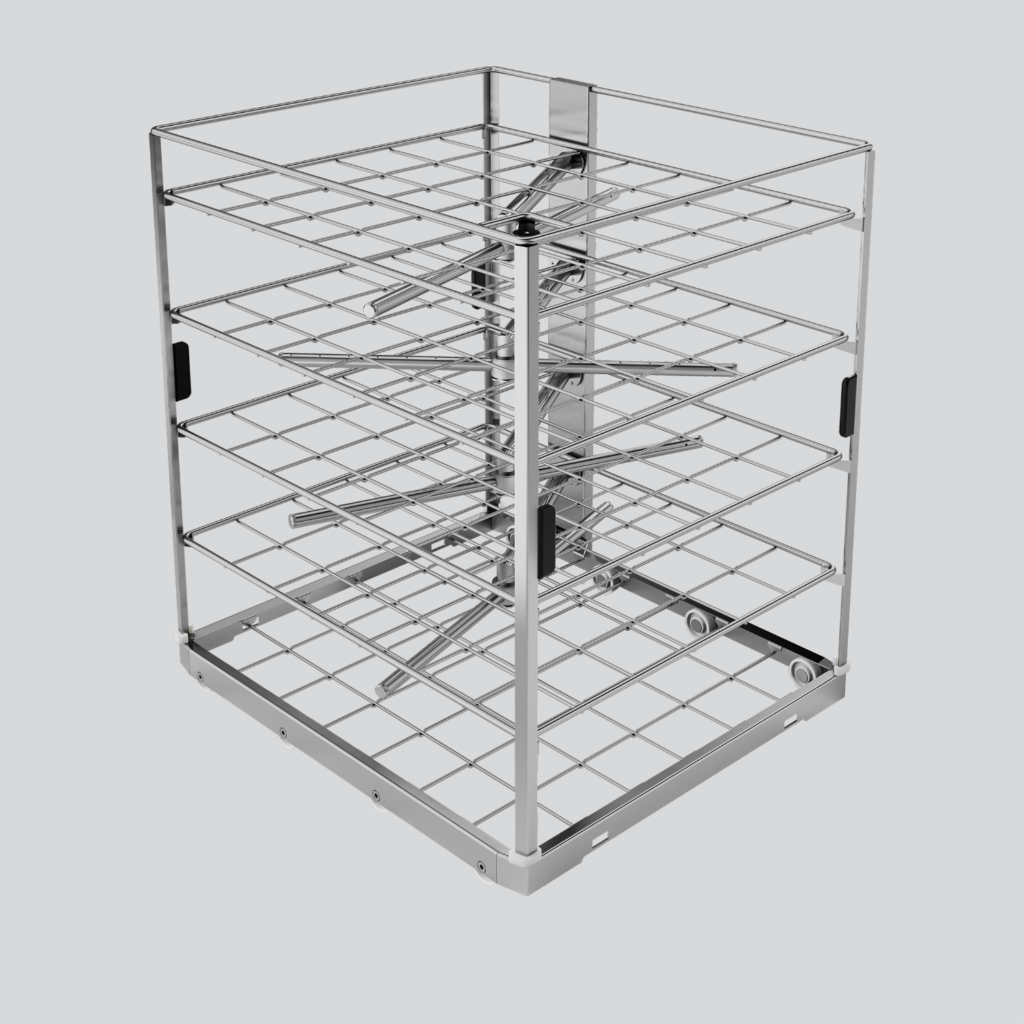

The innovative Flexi Shelf System is designed for the Life Science, making it possible to equip the machine with up to three shelves for easy and ergonomic loading and unloading. In short – the shelves can be tailored exactly to your needs with every wash.

The IQ5 is also available with regular racks, and with the option of one or two doors. The doors can be either automatic sliding doors or manual drop down doors that can be used for loading.

Great capacity with a wash chamber with a total volume of 279L, several different rack- and module options and a wash cycle around 35 minutes.

The IQ-series guarantees the execution of optimal, reliable, and safe processes at the lowest cost. The IQ5 is engineered to minimize water, power, and chemical consumption, hereby leaving a lower carbon footprint.

The IQ5 is compatible with the automatic AL10 robot and allows robotic loading and unloading, reducing heavy lifts and improving the working environment.

It can be placed in compact spaces if needed and thus you can benefit from the frontal service access.

The design of the large chamber allows you to be efficient and wash more items per cycle.

Engineered to reduce consumption and set new standards while saving water, electricity, and chemistry.

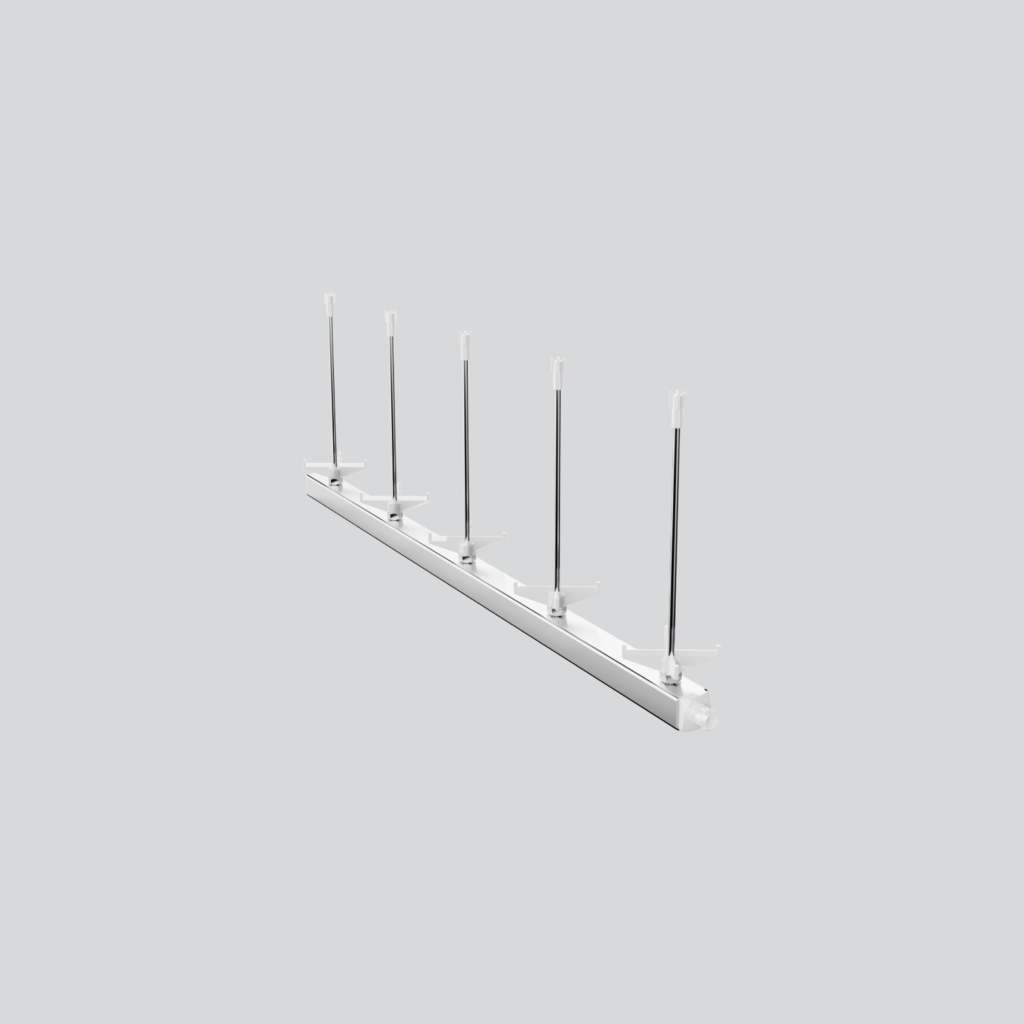

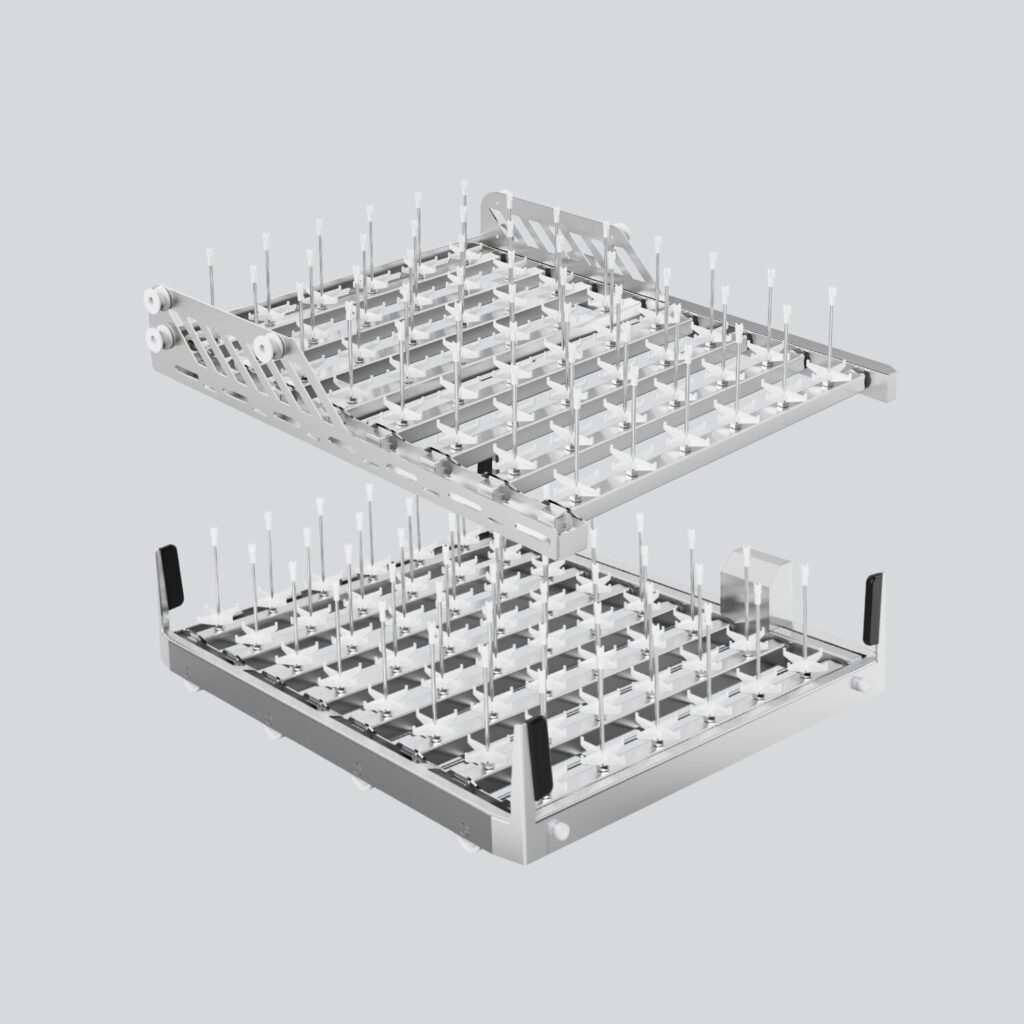

The Flexi Shelf System

With the Flexi Shelf System, it is possible to equip the machine with the appropriate accessories for any laboratory wash load.

In fact, the Flexi Shelf System can be designed to provide full chamber height in the front of the chamber, while several levels of spikes are located in the back of the chamber for smaller glassware.

Unlike the rack system, only replacing or adding one or two distributors results in a complete change in your interior design.

Sliding or Manual Door?

The IQ5 comes with several options concerning doors. It is possible to choose between automatic sliding doors or manual drop down doors that can be used to load racks.

It is optional to get one or two doors, depending on your needs for a clean and unclean side. The double door models ensure an effective barrier between the unclean and the clean side, optimizing the required level of hygiene and reducing the risk of hospital infections as well as keeping a safe working environment for the staff.

Contact us if you need guidance to choose the right option for your specific needs.

Meet the AL10

The autonomous robot is the perfect match for your Washer Disinfector. The AL10 is the obvious choice if you need to maximize the efficiency and overall output. Each AL10 connects with up to 8 Washer Disinfectors and secures optimal process flow at all times.

See our case about the AL10 or click below to read more.

There is another way

We have a common duty to do better for our planet. At KEN we ask, “is there another way?”. We challenge the massive usage of single-use items in the Healthcare and Life Science industries, and we always aim to evolve our solutions and options with environmental responsibility in mind.

Read more about our initiatives.

Accessories

Additional information

If you are looking for certificates, please see our certificates overview.

Cases